The main forming methods for cemented carbide rods include extrusion molding, die pressing, injection molding, cold isostatic pressing, etc. In actual production, the most suitable process is selected based on the rod diameter, length, tolerance requirements, and batch size.

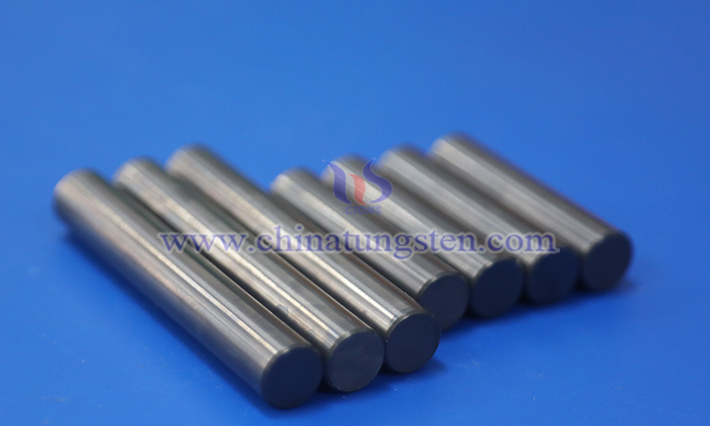

CTIA GROUP LTD Cemented Carbide Rods Pictures

1.Extrusion Molding

The most common and efficient production method for cemented carbide rods, especially for solid rods and rods with cooling holes (single hole, double hole, triple hole straight hole or spiral hole) with diameters from Φ3 to Φ50mm.

Process: Batching → Mixing → Granulation → Extrusion (extruded through cemented carbide die) → Cutting → Pre-sintering to remove plastic → Sintering.

Advantages: High production efficiency, high material utilization rate, capable of forming complex cooling hole structures, good straightness of rods.

2.Die Pressing (Compression Molding)

Suitable for small-diameter (generally ≤Φ8mm), short-length, or special-requirement rods, also commonly used for segmented pressing of ultra-long rods (>400mm).

Process: Load plasticized material or powder into a steel mold, and use a hydraulic press for unidirectional or bidirectional pressing.

Advantages: High dimensional accuracy, good density uniformity; Disadvantages: Low efficiency, fast mold wear, not suitable for rods with holes.

3.Injection Molding (Metal Injection Molding, MIM)

In recent years, it has been used to produce cemented carbide rods with small diameters (Φ0.5 to Φ10mm), complex shapes, or thin-walled with holes.

Process: Powder + polymer binder mixing → Injection molding machine injection → Debinding → Sintering.

Advantages: Capable of forming extremely complex internal hole structures, high dimensional accuracy; Disadvantages: High cost, slightly lower strength than traditional processes, mainly used for high value-added products.

CTIA GROUP LTD Cemented Carbide Rods Pictures

4.Cold Isostatic Pressing (CIP)

Usually used as an auxiliary process in combination with other forming methods, pure cold isostatic pressing is rarely used directly for long rods.

Process: First extrude or press into a rough blank → Encapsulate and cold isostatically press → Turn to the required size.

Advantages: Mainly used when extremely high density uniformity is required, for ultra-large diameters (>Φ80mm) or ultra-long rods (>600mm).

5.3D Printing/Additive Manufacturing (Emerging Process)

In experimental stages, using selective laser melting (SLM) or binder jetting + sintering processes to produce cemented carbide rods, mainly for prototype development or extremely complex internal cooling structures, not yet in large-scale mass production.