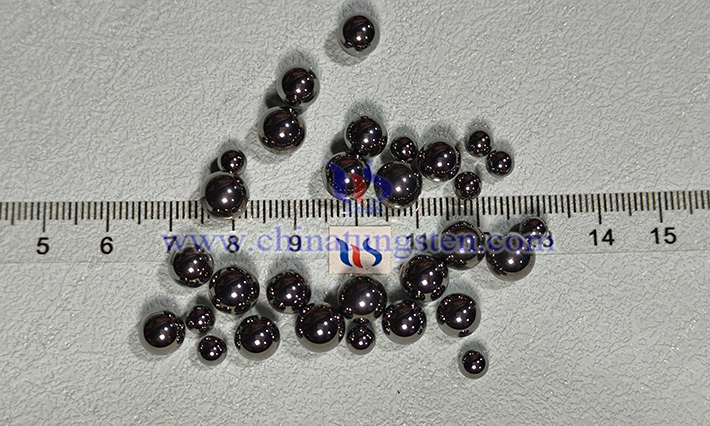

Tungsten beads are widely used in grinding media, sandblasting, valves, bearings, and other fields, exhibiting wear resistance far exceeding that of ordinary steel or ceramic beads. The wear resistance of tungsten beads primarily stems from their extremely high hardness and the composite structure of tungsten carbide (WC) particles and the binder phase. The main factors influencing the wear resistance of tungsten beads can be categorized into two main types: material-specific factors and environmental factors.

1. Influence of Material Structure on the Wear Resistance of Tungsten Beads

WC Grain Size: Fine grains (submicron to nanometer scale, 0.2-0.8μm) offer higher hardness and better wear resistance, especially against micro-cutting and polishing wear. Coarse grains (>2μm) offer better toughness, but relatively lower wear resistance.

Cobalt (Co) or Other Binder Phase Content: Low cobalt content (5-8%) results in high hardness and excellent wear resistance, but poor toughness/impact resistance, making them prone to chipping. Medium to high cobalt content (10-15%) significantly improves toughness, making it suitable for impact-prone conditions, but reduces hardness and slightly decreases wear resistance. Ultra-low cobalt or non-magnetic (nickel-based/iron-based bonding): Offers better corrosion resistance in certain special applications, but wear resistance requires comprehensive evaluation.

Tungsten carbide phase purity and distribution: Uniform, dense WC particles with no obvious porosity offer better wear resistance. The presence of free carbon, graphite, η phase (brittle phase), or coarse carbides significantly reduces wear resistance.

Density and sintering quality: Tungsten beads with near-theoretical density (≥99.5%) have fewer internal defects and higher wear resistance. High porosity or insufficient sintering leads to early spalling and accelerated wear.

Surface treatment/coating: Coatings such as DLC, TiN, and TiAlN can further reduce the coefficient of friction and improve initial wear resistance, but these coatings wear off quickly under high-wear conditions.

2. The Influence of Operating Environment on the Wear Resistance of Tungsten Balls

Wear Type: Abrasive wear, hardness is dominant, fine-grained low-cobalt is optimal. Impact wear/fatigue wear, toughness is more important, medium-cobalt or coarse-grained is better. Adhesive wear/high-temperature friction, low coefficient of friction and red hardness (thermal stability) are key.

Hardness of the grinding media: The harder the grinding media, the faster the tungsten ball wears, especially when the hardness of the grinding media is close to or exceeds that of the tungsten ball.

Media Environment: Corrosive media (acids, alkalis, salt water) accelerate cobalt dissolution, drastically reducing wear resistance. High-temperature environments (>600–800℃) soften the binder phase, reducing wear resistance.

Grinding speed, pressure, solid-liquid ratio: High linear velocity and high pressure environments cause severe heat generation, softening of the cobalt phase, and accelerated wear. Wet grinding generally provides better wear resistance than dry grinding.