The wear resistance of tungsten beads typically refers to the wear resistance of cemented carbide (CMC) balls, which are primarily composed of tungsten carbide (WC). CMC is currently recognized in the industrial field as one of the most wear-resistant grinding media. Its core advantages lie in its extremely high hardness and excellent wear resistance, making it outstanding in high-intensity grinding, dispersion, and ball milling processes, far surpassing ordinary steel balls, zirconium oxide balls, and alumina balls.

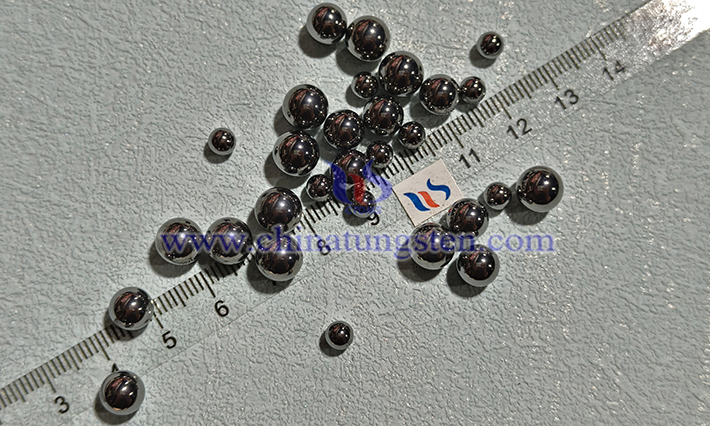

Tungsten beads are primarily composed of tungsten carbide (WC), comprising 70%–97%, supplemented with metals such as cobalt (Co) and nickel (Ni) as binder phases. They are formed under high pressure and sintered at high temperature using powder metallurgy processes. This structure endows tungsten beads with extremely high hardness, typically reaching 89–95 HRA (equivalent to 69–81 HRC), approaching the hardness level of natural diamond (Mohs hardness 8.9–9.1). High hardness is fundamental to wear resistance. The harder the material, the less likely it is to be scratched or cut by other substances, thus significantly reducing the wear rate.

In terms of wear resistance, tungsten beads exhibit extremely low wear rates, typically only a fraction of those of ordinary steel balls, and even several times to more than ten times lower than high-quality zirconia beads. For example, in nanoscale grinding of high-hardness materials (such as titanium dioxide, electronic ceramic slurries, and positive and negative electrode materials for lithium batteries), tungsten beads can control dielectric loss to extremely low levels while avoiding the introduction of impurities that contaminate the product. Some high-end tungsten beads (such as pure tungsten carbide or low-cobalt/nickel bonding systems) maintain excellent wear resistance even in acidic and alkaline corrosive environments.

Wear resistance is also closely related to microstructure. Fine-grained (submicron) or ultrafine-grained tungsten beads have a more uniform microstructure, higher density (14.5–15.5 g/cm3), and more grain boundaries, which effectively inhibit crack propagation and further enhance resistance to abrasive wear and fatigue wear. In high-energy ball mills, tungsten beads can withstand intense impact and shearing, exhibiting significantly lower wear than traditional grinding media and extending their service life by 3–10 times.

In practical applications, tungsten beads are widely used in lithium battery slurry grinding, fine dispersion of electronic ceramic powders, ultrafine grinding of pigments/coatings, and processing of high-purity materials in pharmaceuticals/chemicals. Due to their low replacement frequency, low contamination, and high grinding efficiency, they offer excellent overall economic benefits.