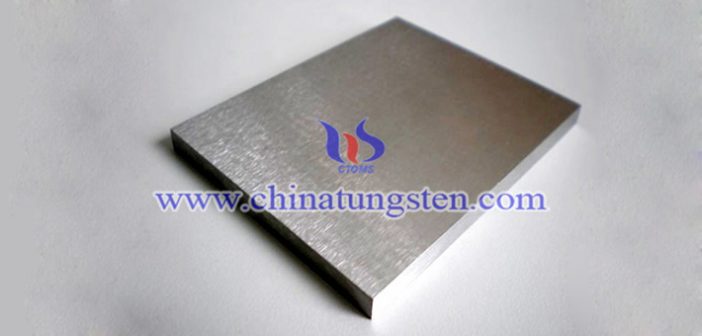

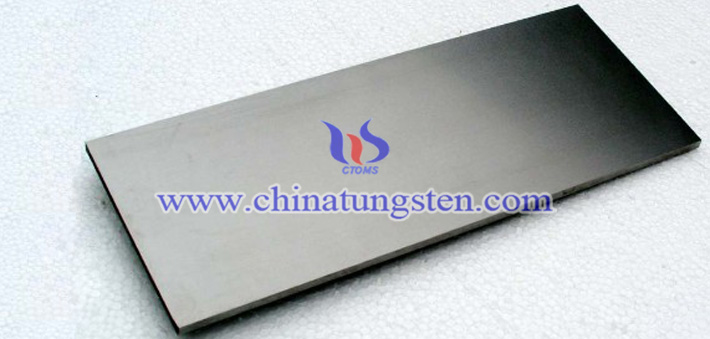

Tungsten plate has a wide application and becomes more and more common seen with the rapid development of nuclear industry and aviation industry. While tungsten plate is easily layered and cracked during rolling process as tungsten has high melting point and high ductile-brittle transition temperature. And the grain size of tungsten is so coarse that it will reduce the mechanical properties of the tungsten plate product, and therefore affect the service life of the downstream tungsten product. So, it has significance for the development of tungsten plate industry to optimize the rolling process of pure tungsten plate.

Rolling Process of Pure Tungsten Plate

Heat the tungsten plate to a certain temperature, and hold for a certain period of time, then carry out cross rolling. Cogging is an important stage during rolling process.

In the cogging stage, tungsten plate is firstly rolled in the width direction, and then rolled in the length direction by turning around 90° until this stage is completed. After that, cover the plate with lime powder to avoid oxidation. Wash the plate after it is cooled in the lime powder. The plate is placed in a molten caustic soda tank and removed from the solution until its surface is dissolved, cooled, then washed in an acidic solution, and finally washed with water. You should remove scale and eliminate cracks on the surface of the plate and turn around the plate again by 90° for rolling until the product is obtained.

More details, please visit:

http://www.tungsten.com.cn/tungsten-plates.html